tig welding sheet metal without filler rod Lately I have been doing a lot of tig welding on steel parts without filler rod. I call it fusion welding but not sure if that is correct. I am really happy with the results, excellent . Known as star bolts or star anchors, they're not strictly decorative. Instead, the star is the washer for an iron rod placed through a sagging or compromised wall to preserve its.

0 · welding tig filler rod chart

1 · tig welding wire size chart

2 · tig welding rods chart

3 · tig welding filler wire chart

4 · tig rod size chart

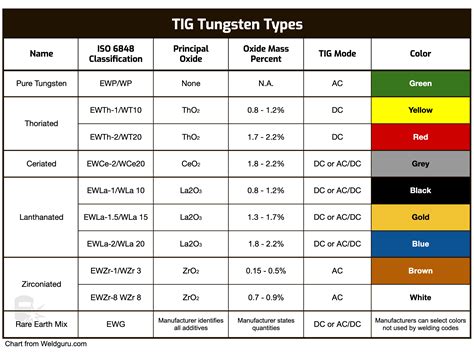

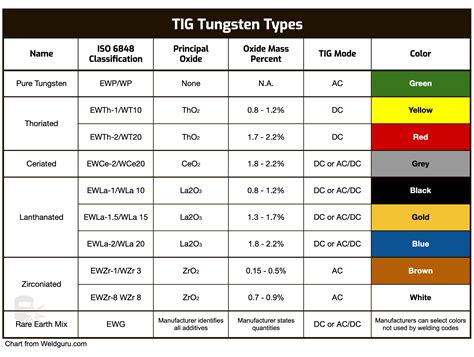

5 · tig rod color chart

6 · stainless steel filler rod chart

7 · stainless filler rod chart

Apply an acrylic or enamel paint you like with a paintbrush. Cover every inch and corner on all sides of the tool box. Paint the handles and latches the same way for a polished look. Coat the latches and handles in a different color for uniqueness. Allow the newly-applied paint to dry for about 24 hours.

Lately I have been doing a lot of tig welding on steel parts without filler rod. I call it fusion welding but not sure if that is correct. I am really happy with the results, excellent . Absolutely, you can engage in TIG welding without the need for a filler rod. This remarkable technique, commonly referred to as autogenous TIG welding or fusion welding. It empowers welders to create seamless weld joints .

Explore Autogenous TIG Welding, a fusion method without filler rods. Learn its advantages, challenges, and ideal scenarios for clean, precise welds. One of the factors in choosing between ER70S-2, -3, or -6, will be the type of steel and the amount of contaminants such as rust and scale you intent to weld through. The .

Preventing burn-through and warping when welding sheet metal is all about controlling the heat. Choose the right welding process and filler metal, and follow these common tips to help ensure success.1/16 filler on 1/16 sheet metal doesn't work well. The amount of heat required to melt the sheet is vasty different from the heat for both sheet and filler. 16 gauge sheet metal is much, much easier with .040 filler. The heat range is better. If you can't get some tig wire, you can uncoil a spool of .045 might wire. Welding auto body sheet metal can present challenges for welders but Ron Covell is here to help mitigate warping with both MIG and . TIG Torch Consumables; Welding Wire & Rod; Plasma Torch Consumables; Helmet . #welddotcom #welding #tigweldingIf you are interested in TIG welding, you might be interested in knowing when it is necessary to use filler wire and when you.

Learn to TIG sheet metal for a perfect weld, covering the basics of tungsten selection, filler metal, settings, metal prep, tack welding, and troubleshooting. . where you fuse the edges of the sheet metal together without adding any filler. This can produce a very clean and smooth weld, but it requires a lot of skill and precision, as you .

Running hot but fast means the metal melts faster, without having to linger in the one spot for as long, keeping the actual heat levels lower. . You want your filler to be melting before or at the same time as your base metal. If you have a filler rod that’s too thick (like using a 2.4mm rod on 1mm metal), then you’ll need more time and .

How to TIG weld aluminum without filler rod. The keys to TIG welding aluminum without filler rod are in the cleaning of the material and the fitting of the joints. The aluminum oxide layer must be removed using a stainless-steel wire brush and acetone. The process requires joints with no gaps. Materials that are thicker than 1/8” work best. How TIG welding sheet metal works. In TIG welding, material is supplied manually with the help of a bar or automatically with a spooled wire. This procedure is suitable for performing high quality welds in case of joining thin stainless steel thicknesses by melting the edges, with small additions of material (in some cases even without filler material). . The factors that will affect the mechanical strength of any weld metal, whether it was made with or without filler material, will be the cleanliness of the steel surface, the impurity levels in the steel, the steel chemistry and it's carbon equivalent, the purity and effectiveness of the inert shielding during welding, and the cooling rate of .Sheet Metal Equipment; Spindle Moulders & Routers; Stands & Supports; Tool Sharpeners; . TIG Torches; TIG & Oxy Filler Rods; Tools & Clamps; Trolleys & Stands; Welding Electrodes; Welding Flux Dips & Sprays; . Bossweld 4043 TIG Welding Rods 3.2mm Aluminium Alloy A5.10 ER4043 - 5.0kg . 9.00. SKU: 300017N.

i was really finding it hard to get a little puddle going without burning through. . buy a one pound tube of 1/16" Silicon-Bronze tig filler. No other filler has a lower melting point AFAIK. . This rod is designed for sheet metal welding. Barry Milton _____ HTP Invertig 201 HTP MIG2400 Miller Trailblazer 302, Spoolmatic 30A, Suitcase 12RC . This is some 1/8th 304 SS flat bar being welded to a 316SS pipe nipple that has a .120" wall thickness. There are no stresses on this part to speak of, so i. 3. Adjust Your Torch Angle. Changing the torch angle when MIG welding goes a long way to preventing burn-throughs. Make sure you adjust the angle to shorten the distance between the tip and the metal, no matter the welding position you work in.This will make the arc more stable, giving you more control over the weld and lessening the chance of burn-through.You can also stagger your tig welds instead of running along the metal in one straight line. Start your weld at one end, do your stitch weld then jump back to the other end then come back again. Alternating back and forth to join in the middle. In general though, tig welding sheet metal can be done like tig welding any other metal.

Buy TIG Filler Rods for Dissimilar Steels from Welding & Welder at prices that can't be beat. Rated Excellent on Trustpilot. Sales & Technical Advice: +44 (0) 1752 936 028After you learn basic welding safety, the basics of tig welding, machine settings, electrode basics, and metal preparation, its time to light up. The first skill drill we are going to do is just welding tig beads without using any filler metal. This drill . MIG vs. TIG Welding: Key Differences. MIG (Metal Inert Gas) welding and TIG (Tungsten Inert Gas) welding are two popular welding methods, each with distinct advantages: Weld Speed: MIG welding is faster, ideal for .

I am new to welding and am trying to butt weld 22 guage mild steel sheet together I am using a miller dynasty 200 dx tig tried 1/8 ceriated electrode 3/32 lath electrode with argon flow at 20 cfh settings are dc with current ranging from 10 to 50 amps the butt joints are fit fairly tight but you can see light through the gap my problem is the edges of the steel melt away and . TIG Welding Sheet Metal Lap Joints is a video about how I like to weld my sheet metal lap joints. It includes tacking, welding autogenious and with filler. . Most welders are familiar with gas metal arc welding (GMAW), more often referred to as MIG welding, which uses a consumable electrode that becomes the filler material for the weld. Autogenous processes like gas tungsten arc welding (GTAW) or TIG welding, on the other hand, use a non-consumable electrode that does not act as filler material .

The design of these wires is for welding thick sections and improving penetration, so they’re a poor choice for welding sheet metal. TIG Welding (GTAW) . Grind the tungsten tip to a sharp point to weld steel, and use either ER70S-2 filler metal or a silicon bronze rod. You need little heat to melt silicon bronze, making it one of the most . Welding without filler metal is a challenging task that requires a number of steps and processes to achieve. But once you have mastered the procedure, it. . TIG Welding Stainless to Mild Steel for Seamless Welds . February .

welding tig filler rod chart

tig welding wire size chart

You might try a filler rod of Silicon Bronze TIG rod. It’s brazing, reduces warpage, less heat, and softer so cleanuo is easier . too hot and I've found mig welding the whole seem is a nightmare to grind cause the weld will be much harder than the sheet metal I've had some success with Tig no filler but its only ideal for all new .

These include proper tungsten selection and preparation, using the right filler metal thickness, good metal preparation, tacking sheets in place, using minimal filler rod for tacks, starting with a flatter piece of metal, staggering welds, using a pulsing TIG setting, cooling the metal faster, and using a dolly and body hammer to flatten warps. Welding is a joining method that uses heat to fuse two or more pieces of sheet metal, sometimes using a filler rod. The process requires a high level of skill. . with or without a filler rod. Stitch welding: in which weld is applied along short, spaced sections between two . MIG, and TIG welding, in particular, create continuous seams that .

tig welding rods chart

Select an appropriate filler rod for the thickness of the metal being welded and maintain optimal heat control throughout the process. . Use high-quality and pure material without any coatings or oils to avoid weld imperfections. Preparation: Proper cleaning, cutting, and clamping will ensure adequate welding space and minimize contamination .

tig welding filler wire chart

Versatile filler material . Silicon bronze is pretty versatile as a filler material. With a TIG torch, you can put it to use on a number of tasks that range from difficult to impossible with a typical steel filler rod. Of course, using this filler material is not exactly welding — not in the traditional sense at least. To weld sheet metal with solid wires, use electrode positive (EP, or reverse polarity). Don’t attempt to weld thin materials like sheet metal with flux-cored wires, which put more heat into the base metal. TIG welding sheet metal. Forget the larger 1/8-inch tungsten electrode and use a smaller one.

tig rod size chart

Sizing of Junction and pull boxes according to NEC Section 314-28. Today, I will explain Electrical Boxes Volume and Fill Calculations as follows. Part (A), “Box Volume Calculations,” defines .

tig welding sheet metal without filler rod|tig rod size chart